Our engines go through a thorough rebuild process ensuring that all parts of the engine are ready for high demand industrial application.

We take nothing for granted when rebuilding an engine core. Every engine is completely torn down and all wear parts such as the bearings, rings, and valves are replaced and the hard parts such as the crankshaft and connecting rods are cleaned, reconditioned, or replaced as necessary.

Once the engine is torn down the block, cylinder head, and any other large cast iorn or sheet metal parts are baked in our burn-off oven at 750 ° for 8-9 hours to remove all oil and grease.

The burned pieces are then run through our steel shot blaster to remove the ash from the oven processing and make the castings as close to new as possible.

Following the block and cylinder head on through, they have all of their threaded holes retapped and gasket surfaces cleaned and inspected. It's also at this point any general repair is done to them such as crack or casting repair.

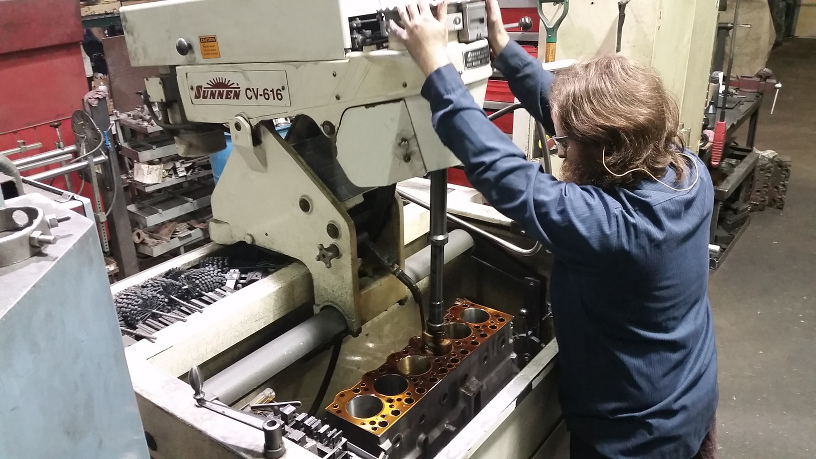

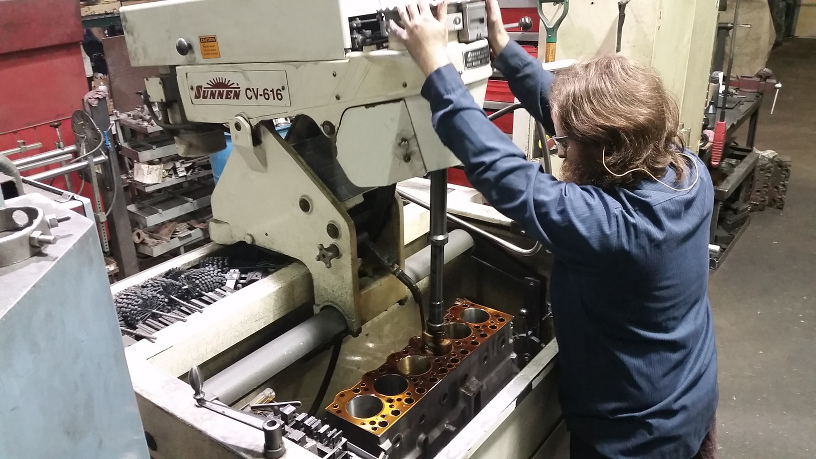

Once they have been cleaned the block is bored, CBN milled, and finish honed to size.

The cylinder head is also CBN milled and the valve seats are re-cut or completely replaced as necessary.

The crankshaft is inspected and reground in our crank grinder.

The connecting rods are cut and re-honed to ensure they are true. The rocker assembly is also reconditioned here and if the engine has solid lifters they are reground to remove any cupping.

The parts such as the gear case, oil pan, and valve cover are tapped, cleaned and brought back to our assembly room. Our assembly room is enclosed from the rest of the shop to keep it as dust free as possible.

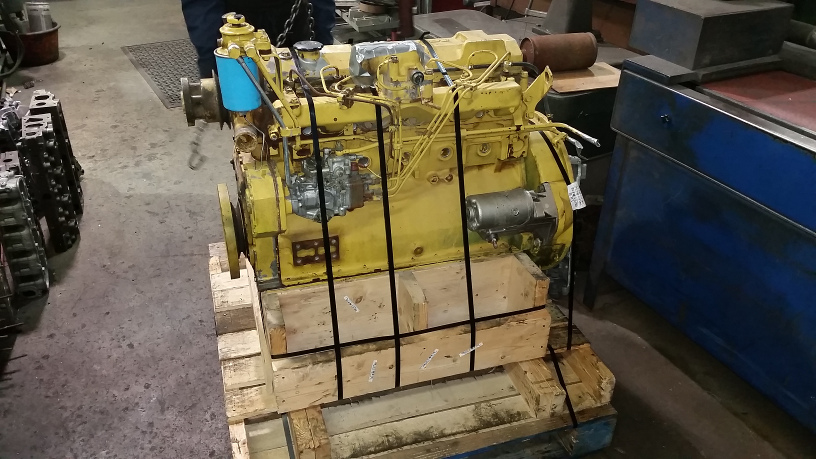

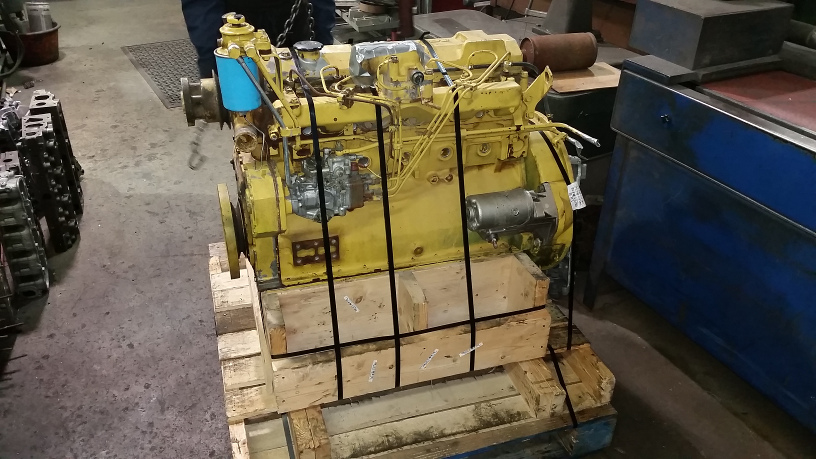

After our engines are assembled the last thing we do is hot test. We have a large variety of manifolds and other necessary pieces to start the engines. The engines are filled with water and oil and ran for one hour or more before finally being packaged for shipping.